Description

Description

Taskmaster Trailer Tires and Wheels – TA28MR

- 15 Inch

- Tire with Wheel

- 5 on 5 Inch

- 205/75-15

- Load Range C

- Steel Wheels – Powder Coat

- Radial Tire

- M – 81 mph

- Taskmaster

Tire with automotive-grade tread has a 6-ply rating and a 1,820-lb max load at 50 psi. Acrylic enamel finish resists damage. Complimentary roadside assistance included. Assembly is match mounted and balanced providing longevity and a smooth ride.

Features:

- Tire-and-wheel assembly is ideal for stock trailers, utility trailers, and campers

- Steel wheel with modular design is sturdy and corrosion resistant

- Black acrylic enamel finish resists chipping and other damage better than powder coat finishes

- Finish is applied after a zinc phosphate pre-treatment and covers an e-coat primer layer

- Excellent corrosion resistance with a salt spray rating of more than 1,000 hours

- Beveled stud holes help to keep wheel securely in place on trailer hub

- Eliminate the need for constant retightening of lug nuts

- Radial tire is constructed with double steel belts and double polyester cords for a long life

- Great for highway use

- Nylon tread-firming belt overlays help prevent tread separation

- Tread depth bars offer a quick visual indicator of tread wear

- Bake tested to ensure that the rubber holds over time

- Automotive-grade tread has sipes that channel water away from the tire to improve traction during wet, snowy, or icy conditions

- Match mounted and balanced for longevity and a smooth ride

- Reduces vibration and the wear and tear it can cause

- Special trailer (ST) tire has sturdy sidewalls so that it can handle heavy loads

- Created specifically for trailers and not intended for use on other vehicles

- 2-Year Platinum Plus warranty includes emergency tire change service and other benefits

- Assembly meets DOT specifications and exceeds FMVSS

Specs:

- Rim dimensions: 15″ diameter x 5″ wide

- Bolt pattern: 5 on 5″

- Wheel bolt size: 1/2″-20

- Wheel capacity: 2,160 lbs

- Pilot diameter: 3.19″

- Offset: 0

- Tire size: ST205/75R15

- Section width: 7.99″

- Outer diameter: 27.13″

- Tire capacity:

- Load range: C

- Ply rating: 6

- Maximum load: 1,820 lbs at 50 psi

- Tread depth: 10/32″

- Max speed: 81 mph (speed rating M)

- 2-Year limited warranty on tire and wheel

Platinum Plus Warranty with Roadside Assistance

This tire-and-wheel assembly comes with a Platinum Plus warranty that includes complimentary roadside assistance for 2 years. If your trailer has a flat tire, call the help line and a technician will come change out the flat tire with your existing inflated spare tire. The service is available 24 hours a day, 7 days a week. In addition to the roadside assistance, this warranty also includes other benefits and services.

Durable Acrylic Enamel Finish

The wheel on this assembly has a durable acrylic enamel finish on the front. The finish is applied after the wheel goes through an environmentally safe zinc phosphate pre-treatment and is coated with an e-coat primer layer. Compared to powder coat finishes, this finish resists getting chipped from flying road debris or scraped from hitting a curb for a longer period of time. These acrylic enamel wheels performed for more than 1,000 hours in salt spray tests.

Beveled Stud Holes

The stud holes on this steel wheel are beveled to ensure that the wheel stays tight against your trailer hub. This also eliminates the need to constantly retorque the lug nuts.

Provider Radials with Automotive-Grade Tread

Unlike standard trailer tire tread, which has solid, continuous ribs, the automotive-grade tread on these Provider radials has ribs with breaks. These breaks allow water to run off to the sides. The Provider tread also has sipes. Siping is a process in which thin grooves (or sipes) are cut into the rubber of the tire. The grooves channel water away from the tread so that the tire makes better contact with the road. Both of these features greatly improve traction during wet, snowy, or icy conditions.

Provider radials are constructed with double polyester cords and double steel belts for increased durability and endurance. A protective layer of nylon is wrapped around the steel belts to help prevent tread separation. Provider radials are bake tested – a process usually reserved for automotive tires – to ensure that the rubber holds up over time.

Match Mounted and Balanced Trailer Tire Assembly

In an ideal world, tire-and-wheel assemblies would be perfectly round and even throughout. Unfortunately tires and wheels have imperfections that often cause vibrations, resulting in a rough ride and wear and tear on the assemblies, as well as on the rest of your trailer’s running gear. Taskmaster helps to solve this problem by match mounting and balancing their assemblies so they’re ready to roll when they reach your door.

To do this, Taskmaster uses a laser-guided machine to locate the heavy and light spots of each assembly. They then align the assembly so that lightest part of the tire is near the heaviest part of the wheel. The assembly is then rotated at high speeds to pinpoint the optimal place to apply weights to further balance the tire.

Don’t delay your adventures by having to take your trailer to the shop for new tires. Start rolling as soon as possible with easy-to-install, fully balanced tire-and-wheel assemblies from Taskmaster.

Radial Tires vs. Bias Tires

Radial ply tires are designed for trailers that are towed on the highway. The cords on a radial tire are positioned at a 90-degree angle to the direction of travel so that they lay across the width of the tire from wheel lip to wheel lip. This construction prevents the cords from rubbing against one another when the tire flexes, unlike the cords on a bias ply tire. As a result, radial tires have less rolling resistance and heat buildup, which leads to a longer tread life and improved steering at higher speeds.

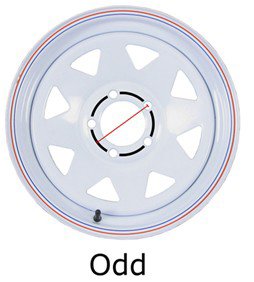

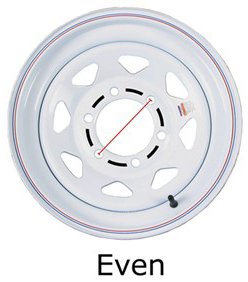

Determining the Bolt Pattern

The first number in the bolt pattern is the number of bolt holes. The second number denotes the diameter, in inches, of the circle on which the bolt holes sit.

To determine the bolt-circle diameter on wheels with an odd number of bolt holes, measure from the center of any bolt hole to the point halfway between the two bolt holes directly across from the first. (Example: “5 on 4-1/2″ means 5 bolt holes with 4-1/2” measured to a point halfway between the opposite bolt holes.)

On wheels with an even number of bolt holes, measure from the center of one bolt hole to the center of the hole directly across from it. (Example: “8 on 6-1/2″ means 8 bolt holes with 6-1/2” from the center of one hole to the center of another on the opposite side.)

Measuring the distance from the center of one bolt hole on the wheel to the center of a bolt hole right next to it can also help to determine the bolt pattern.

- If D = 2-5/8″, then the bolt pattern is 5 on 4-1/2″

- If D = 2-3/4″, then the bolt pattern is 5 on 4-3/4″

- If D = 3″, then the bolt pattern is 5 on 5″

- If D = 3-1/4″, then the bolt pattern is 5 on 5-1/2″