Dexter Trailer Axles – 7359765 3500 lbs 95 Inch Hub Face Spindles Only 80 Inch Spring Center No Drop or Lift No Hubs Leaf Spring Suspension Dexter EZ Lube Spindles Round trailer axle beam measures 95″ from hub face to hub face (when hubs – sold separately – are mounted) and 80″ from spring center to spring center. E-Z Lube spindles make it easy to lubricate bearings (sold separately). Features: Round axle beam acts as part of your trailer’s suspension system Replace an axle on your trailer Fabricate a suspension to fit your application High-strength steel construction Bend in axle creates zero camber angle for even road-to-tread contact across the width of your trailer’s tires Best for straight-line acceleration and steady, controlled towing Underslung design – spring seats welded to underside of axle for mounting leaf springs (sold separately) Low ride height makes it easier to load and unload your trailer Straight, E-Z Lube spindles – no drop Built-in grease zerks for simple lubrication Spring seats, brake flanges, and spindles are welded on Made in the USA Specs: Weight capacity: 3,500 lbs Hub-face-to-hub-face length: 95″ Spring-center-to-spring-center length: 80″ Tubing outer diameter: 2-3/8″ Bearings (sold separately): Inner bearing: L68149 Outer bearing: L44649 Brake flange configuration: 4 bolt Limited 5-year warranty Axle Dimensions Hub Face and Spring Center Measurements on Standard Trailer Axle There are multiple ways to measure the length of an axle beam, but the hub-face-to-hub-face and spring-center-to-spring-center lengths are the most accurate. Hub face (A) refers to the length of the axle measured from the base of one wheel stud to the base of the wheel stud on the opposite side of the axle (when hubs are mounted on the beam). The spring center (B) is the approximate width of your trailer. It is measured from the center of the spring seat on one side of the axle to the center of the seat on the other. This axle beam comes with the spring seats welded on. If you are replacing your trailer’s axle, you should be able to figure out which type you need by determining your trailer’s capacity, the bolt pattern of your wheels, the brake type and the aforementioned lengths. E-Z Lube Spindles Make Lubrication Simple The E-Z Lube spindles on this axle are meant to work with E-Z Lube-compatible hubs to make lubricating your bearings quick and easy. Each E-Z Lube spindle has a zerk fitting on the end. And every E-Z Lube hub comes with a grease cap that has an easy-to-remove rubber plug. Just pop out the plug on the cap to access the zerk on the spindle. When you inject grease into the zerk with a grease gun, the grease will flow to both the inner and outer bearings of the hub, lubricating the bearings and forcing out old, ineffective grease. Once you see new grease beginning to be pushed out, you know that your bearings are fully lubricated. This means that you can lubricate the bearings without the mess of taking apart the entire assembly. Dexters Dexters are made of high-strength steel and come with spindles and spring seats welded on. The spring seats are attached to the underside of the axle so that the leaf springs (sold separately) can mount beneath the axle. The result of this underslung design is a trailer that rides a bit lower for quick and easy loading and unloading. Each axle is manufactured to create a certain camber angle. This ensures that the angle of the wheels is correct for your towing needs. Because the primary concern when towing is maintaining controlled, in-line movement, each axle is made so that your trailer’s tires will run along the pavement evenly, with contact across the width of the tread. The result is excellent straight-line acceleration for steady, in-line tracking. You might notice the bend near the center of the axle; this is what ensures the proper camber angle. Having the center ride a bit higher and the sides of the axle bent lower allows the axle to give just enough to compensate for the load.

Original price was: 328.00$.300.00$Current price is: 300.00$.

Delivery in 2-3days

30days Return Policy

3Years Warranty

Description

Description

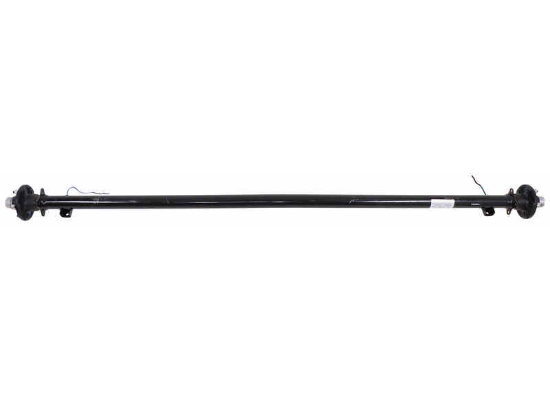

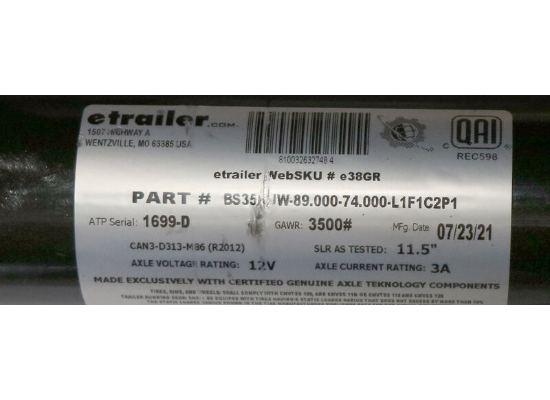

trailer Trailer Axles – e65GR

- 3500 lbs

- 89 Inch Hub Face

- 5 on 4-1/2 Inch

- 74 Inch Spring Center

- No Drop or Lift

- Idler Hubs

- Leaf Spring Suspension

- etrailer

- Easy Grease Spindles

Round trailer axle beam measures 89″ from hub-face-to-hub-face and 74″ from spring-center-to-spring-center. Includes pre-greased idler hubs – with bearings, races, and seals – for 13″ to 15″ wheels.

Features:

- Round axle beam acts as part of your trailer’s suspension system

- Replace an axle on your trailer

- Fabricate a suspension to fit your application

- High-strength steel construction

- Bend in axle creates zero camber angle for even road-to-tread contact across the width of your trailer’s tires

- Best for straight-line acceleration and steady, controlled towing

- Underslung design – spring seats welded to underside of axle for mounting leaf springs (sold separately)

- Low ride height makes it easier to load and unload your trailer

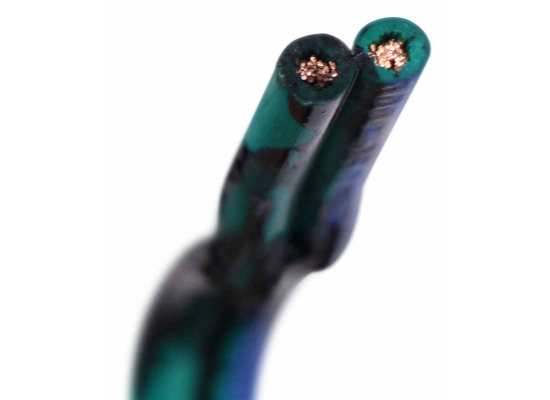

- Straight, Easy Grease spindles – no drop

- Patented welding process prevents spindle failure with 40% stronger welds

- Built-in grease zerk for simple lubrication

- Spring seats and spindles are welded on

- Cast iron idler hubs are sturdy and durable

- Pre-greased idler hubs with bearings, races, seals, and lug nuts – no need to pack bearings

- CSA, QAI, and SAE-N certified

- Lifetime technical support from the experts at etrailer.com

Specs:

- Weight capacity: 3,500 lbs

- Hub-face-to-hub-face length: 89″

- Spring-center-to-spring-center length: 74″

- Hub bolt pattern: 5 on 4-1/2″

- Grease cap flange diameter: 1.988″

- Wheel stud dimensions: 1/2″ diameter x 1-5/16″ long

- Axle diameter: 2-3/8″

- Wheel size: 13″ to 15″

- Limited lifetime warranty

Axle Dimensions

There are multiple ways to measure the length of an axle beam, but the hub-face-to-hub-face and spring-center-to-spring-center lengths are the most accurate. Hub face (A) refers to the length of the axle measured from the base of one wheel stud to the base of the wheel stud on the opposite side of the axle (when hubs are mounted on the beam).

The spring center (B) is the approximate width of your trailer. It is measured from the center of the spring seat on one side of the axle to the center of the seat on the other. This axle beam comes with the spring seats welded on.

If you are replacing your trailer’s axle, you should be able to figure out which type you need by determining your trailer’s capacity, the bolt pattern of your wheels, the brake type and the aforementioned lengths.

etrailer Axles

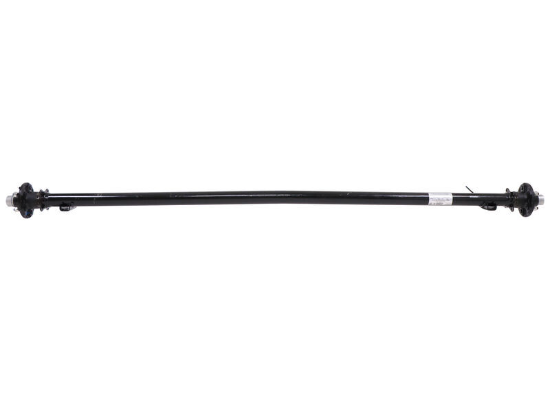

etrailer axles are made of high-strength steel and come with spindles and spring seats welded on. The spring seats are attached to the underside of the axle so that the leaf springs (sold separately) can mount beneath the axle. The result of this underslung design is a trailer that rides a bit lower for quick and easy loading and unloading.

Each axle is manufactured to create a certain camber angle. This ensures that the angle of the wheels is correct for your towing needs. Because the primary concern when towing is maintaining controlled, in-line movement, each axle is made so that your trailer’s tires will run along the pavement evenly, with contact across the width of the tread. The result is excellent straight-line acceleration for steady, in-line tracking. You might notice the bend near the center of the axle; this is what ensures the proper camber angle. Having the center ride a bit higher and the sides of the axle bent lower allows the axle to give just enough to compensate for the load.

Bearing, Race, and Seal Information

- Bearings (included)

- Inner bearing: L68149 (1.378″ inner diameter)

- Outer bearing: L44649 (1.063″ inner diameter)

- Races (included)

- Inner race: L68111

- Outer race: L44610

- Grease seal (included): 58846

- Inner diameter: 1.719″

- Outer diameter: 2.565″

Thoroughly Tested for Safety

This hub-and-drum assembly meets the requirements for certification by the Canadian Standards Association (CSA). The CSA creates standards, which when complied with ensure a safe and quality product. This assembly underwent extensive testing to measure stopping distances when braking. This assembly has also been tested by QAI Laboratories for braking performance in a complete automotive setup and under real-world conditions to provide the most realistic scenario for the everyday driver.

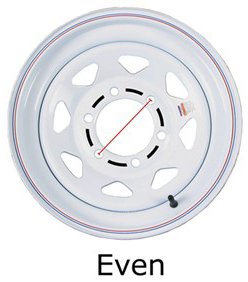

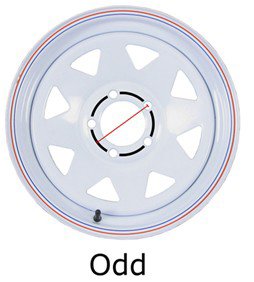

Determining the Bolt Pattern

The first number in the bolt pattern is the number of bolt holes. The second number denotes the diameter, in inches, of the circle on which the bolt holes sit.

On wheels with an even number of bolt holes, measure from the center of one bolt hole to the center of the hole directly across from it. (Example: 8 on 6-1/2 means 8 bolt holes with 6-1/2″ from the center of one hole to the center of another on the opposite side.)

To determine the bolt-circle diameter on wheels with an odd number of bolt holes, measure from the center of any bolt hole to the point halfway between the two bolt holes directly across from the first. (Example: 5 on 4-1/2 means 5 bolt holes with 4-1/2″ measured to a point halfway between the opposite bolt holes.)

Measuring the distance (D) from the center of one bolt hole on the wheel to the center of a bolt hole right next to it can also help to determine the bolt pattern.

- If D = 2-5/8″, then the bolt pattern is 5 on 4-1/2″

- If D = 2-3/4″, then the bolt pattern is 5 on 4-3/4″

- If D = 3″, then the bolt pattern is 5 on 5″

- If D = 3-1/4″, then the bolt pattern is 5 on 5-1/2″